3.5 hrs

Actually spent almost the whole day on the plane, except for watching the Longhorns take on Central Florida.

Started with drilling the 708B angle. This is hard work, and three hands would be handy. Imagine a race of aliens that has four hands. Just think of the fantastic things they can build. I bet they wish they had six hands.

With the skins lifted up, drilled the front 656 gussets.

Edge deburred and started fitting 6111 ribs. The first thing I did was cut the left one too short. I started on the right side and got it mostly passable, but I ordered two new ones and will do it over.

The instructions and drawing are almost no help, except for defining the two boundary conditions. Look at Smitty's page, he got it right the first time, and has a good method. I think the trick is not to reduce the length at the top, just shape the flanges as Smitty shows.

Post Edit. They are already the right length. They only need some flange bevelling.

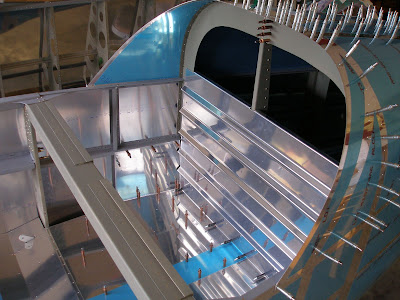

Cleco baggage compartment covers and floors. I'm not going to rivet these in yet.

Finish deburring seat backs. Started these a while back and just wanted to finish the tedious work.

Fit and match drill 751 baggage bulkhead. It all starts looking very cool!

The new 9 kits ( and probably the 7's) have a bend/bevel on one long edge of the 652 bulkhead. There is absolutely no mention of this in the plans. Currently asking around to see what others have done with this feature.

Oh, and I committed to buying an engine today, which means I have all the info I need to mail the finish kit order. The engine will be a O320-E2A, with 0 hrs since major overhaul, 160hp pistons and cam, chromed ECI cylinders, brand new Skytech starter, 60A alternator, freshly overhauled carb, and a Vetterman exhaust. I paid a bit more than I wanted to, and I really wanted a injection setup, but it will be a very good engine.

Also place an order with Van's for the 6111's, am aileron trim kit, an AHRS mounting kit, and a couple of other misc items.